Leightweight ceramic components from the 3-D printer

Material savings for the same load capacity.

Producing ceramic components through an innovative 3-D printing process – this is the goal of a project by the company WZR ceramic solutions GmbH, of Rheinbach. The advantages are obvious: the 3-D printing makes it possible to flexibly manufacture, in almost any manner desired, complex geometries and inner structures. However, the powder-based 3-D printing in the area of ceramic material has been researched, but seldom implemented industrially up to now.

Thus, WZR ceramics has set itself the challenge of putting into practice a machine- and software concept, selecting and then investigating the relevant raw materials, developing an appropriate binder concept, and setting the process parameters for optimal component qualities.

Material savings for the same load capacity

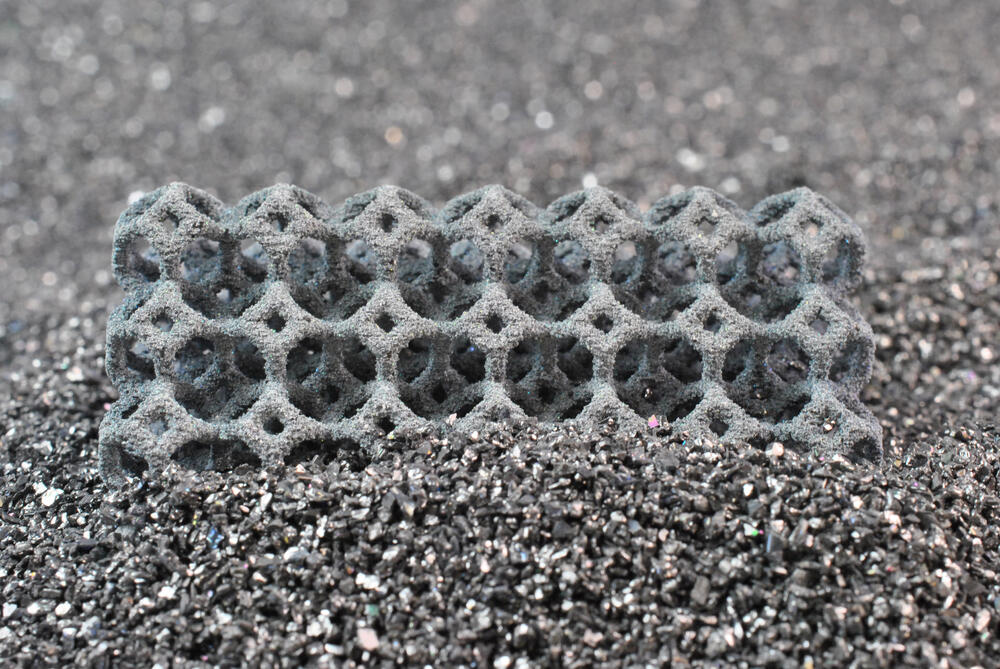

A second project section aims to also improve the structure of the ceramic components and thus spare resources. Specifically, the new procedure is intended to make it possible to vary the material density within a component and thereby reduce the amount of building material in areas under less strain – through, for example, bionic pore structures. Through a skillful combination of »material and hollow spaces«, material-efficient building parts can be constructed which nonetheless have the same stress capacity as traditional parts.

Beyond this, the 3-D printing also offers the possibility of using different ceramic materials in a single component. Thus qualities such as density, resilience and stability can be locally adapted in a targeted manner and oversizing can be avoided. The decoupling of workpiece shape, workpiece mass and workpiece stability sought in the project offers a potential for lightweight design with massive weight savings of some 30 %.

Project implementation:

WZR ceramic solutions GmbH

Lise-Meitner Str. 1

53359 Rheinbach

Telefon: 02226 | 1698-10

info@wzr.cc

www.wzr.cc

AZ 32014