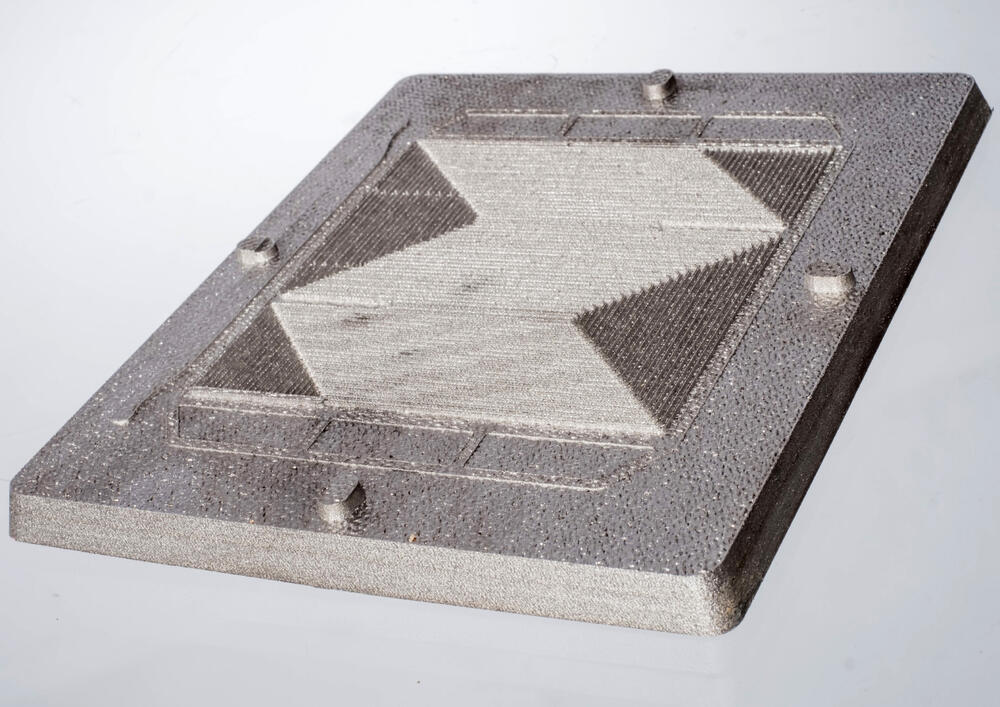

Prototypes for fuel cells from the 3D printer

Resource-efficient manufacture of tool inserts for metal bipolar plates

Metallic bipolar plates are used in electrochemical energy converters such as fuel cells and electrolyzers. In fuel cells they are responsible for the distribution of oxygen and hydrogen and make it possible for electricity to be conducted. In the manufacture of sheet metal for these plates, punching tools and forming dies (negative forms) are necessary. Up -to now these prototype tools, even in small batch production, have been manufactured with steel at some cost and effort – with accompanying long manufacture times up to a number of months.

The company Eisenhuth GmbH & Co. KG (Osterode, Harz) has a new, resource-efficient 3D printing process for the manufacture of tool inserts for metal bipolar plates. It enables a simpler, more flexible and affordable production of press tools in comparison to metal molds, which also simplifies the manufacture of test prototypes, small batches and series start-ups.

It was the goal of extensive investigation in cooperation with the Direct Manufacturing Research Center (DMRC) and the University of Paderborn to identify a synthetic material appropriate for use in tools, and the best possible machine- and process settings for the new printing procedure. The market potential for the sheet metal bipolar plates is seen to be based, above all, on the combined chemical stability and mechanical resilience of the new materials. The concept as developed can also be extended to other processes, such as the manufacture of heat exchangers.

Project implementation:

Eisenhuth GmbH & Co. KG

Friedrich-Ebert-Straße 203

37520 Osterode am Harz

Telefon: 05522 | 9067-14

E-Mail: t.hickmann@eisenhuth.de

www.eisenhuth.de

Cooperation partner:

Direct Manufacturing Research Center (DMRC)

an der Universität Paderborn

Mersinweg 100

33098 Paderborn

https://dmrc.uni-paderborn.de

AZ 32644